Aoda Dumas Nitrogen Protein Analyzer

Dumas Nitrogen Protein Analyzer determines the nitrogen protein content of samples through combustion, purification, reduction, and thermal conductivity detection....

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Aoda Dumas Nitrogen Protein Analyzer

Dumas Nitrogen Protein Analyzer determines the nitrogen/protein content of samples through combustion, purification, reduction, and

thermal conductivity detection.

It efficiently analyzes a single sample in 4 minutes without pretreatment and reacts in a nontoxic and harmless way to ensure safety and

environmental friendliness.

Considerable: a 1-disc 120-position autosampler (D200 only) is adopted to directly analyze a large number of samples

Quick: the fast cooling function helps the device reach the shutdown temperature in 30 minutes

Premium: core pneumatic components of SMC® and mass flow controllers of Bronkhorst® retain the reliability for a long time

Cost-effective: new consumables and efficient metal condenser dewatering technologies extend the service life

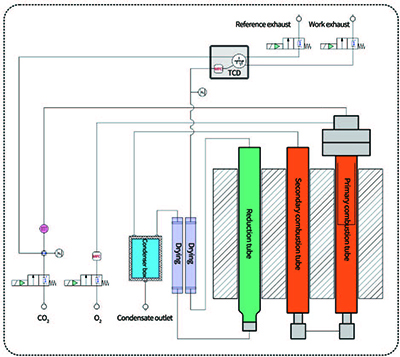

Two-stage combustion and oxidation: pure oxygen combustion in the primary combustion tube facilitates preliminary oxidation and

digestion of a sample;

The remaining part slides through the secondary combustion tube, together with the carrier gas, and is completely digested after being

oxidized by the mixture of Pt catalyst and copper oxide.

Three-stage dewatering: most of water is removed by an electronic condenser so that the desiccant can work; traces of water is removed

by primary and secondary drying tubes.

Efficient reduction: an efficient reduction agent reduces nitrogen oxides to nitrogen gas and absorbs excess oxygen;

TCD detection: the thermal conductivity detector (TCD) can determine the nitrogen produced by reduction.

Applications

The Dumas Nitrogen Protein Analyzer is widely used to determine the total nitrogen content in diesel exhaust fluid, cereals (grain), seeds, meat, meat products, animal feed, dairy products, red wine, fertilizers and soil.

Product Features

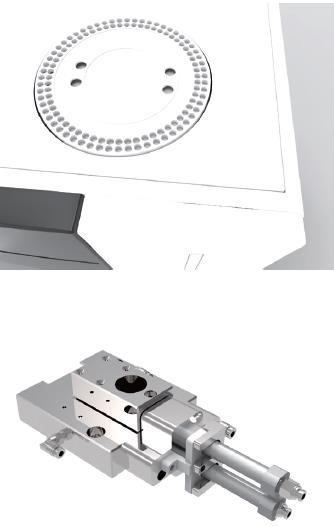

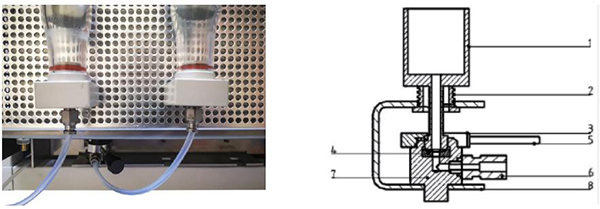

Sampling System

SMC® pneumatic components can inject samples for 100,000 times, with low maintenance costs

The contactless in-situ detection function provided by anti-interference infrared modules can interrupt self-test and pop up message to

avoid maloperation if the sampling disc is occupied (DUMAS200 Only)

Users can add samples freely during preparation (either solid or liquid) to enhance experimental efficiency, without stopping the automatic analysis.

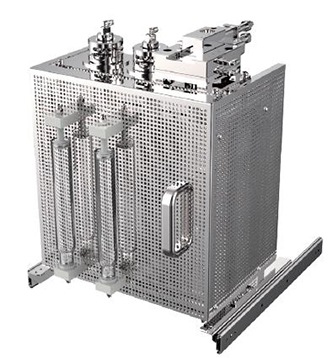

Combustion Furnace System

High-temperature, pure oxygen, and the two-stage combustion process ensure thorough oxidation and digestion.

An efficient metal condenser and two-stage desiccants can completely remove water.The disccants can be reused for 20,000times.

New consumables can reduce nitrogen oxide, absorb excess oxygen, and prolong the service life.Both combustion and reduction

tubes can be reused for 1,000 times.

Pneumatic System

A two-stage regulator eliminates the impact of external pressure fluctuations and combustion-included pressure changes on the

dtector system to ensure stability.

PTFE fittings and SMC® quick couplers allow for clear observation of Contaminants and toolless maintenance

The combustion tube and joint of an original pneumatic connector supprt easy assembly and disassembly to elimate air leakeage

caused by irreversible wear of ferrule compression fittings

Software Function

Windows Chinese Version streamlines operation and improves efficiency. Click to configure parameters and conditions, and control the

computer to gather, process, store and print out data.

Wireless communication of balance data: an industrial wireless communication module automatically collects weight data, with the max

distance of 100m. The data display window and voice authentication function can adjust value (D200 Only)

Air leakage inspection: the gas path can be checked automatically or manually for the convenience of users

Custom lab report: report format, company name and logo, etc. can be customized

Standby/wake-up function: it reduces the on/off frequency and enhances the experimental efficiency. Carrier gas, power consumption and

cost are lowered in standby mode

Intelligent oxygenation function: the software adds oxygen subject to changes in conditions and samples to save reduction agents.

Solution library: a solution library is built in and there’ s no need to develop new approaches

Periodic maintenance reminder: time and cycle of consumable replacement are determined based on sample features, quantity, oxygen

consumption, etc., and reminders will be issued timely

Self-diagnosis: if experimental conditions are not up to standard or not prepared, users can choose from 23 fault diagnosis methods to

automatically raise a pop-up alarm

Data processing: experimental results can be easily reached by RSD and mean value calculation

lalibration method: accurate experimental data are output by one point or multiple points

Audit trail: the software has developed user permission hierarchy rules for easy traceability in accordance with FDA 21 CFR Part 11(D200 Only)

LIMS: the software share data with the laboratory information management system

Technical parameters

| Analysis efficiency | 3-4 min each |

Weighing accuracy | <0.1mg |

| Detection range | 0.1-500mg nitrogen |

| Detection recovery rate | >99.5% |

| Relative standard deviation (RSD) | ≤0.5% (150mg standard 10% nitrogen) |

| LOD | 0.01mg nitrogen |

| Sample weight | Solid ≤1g, liquid ≤1mL |

| Operating system | Windows 7 and above |

| Sampler | D200:1 disc x 120 1 disc x 40 positions D50:1 disc x 60 positions |

| Detector | TCD |

| TCD accuracy | ≤0.01℃ |

| Carrier gas | CO2 |

| Furnace temperature | 1200℃ |

| Carrier gas purity | >99.999% |

| Internal module communication mode | RS485-bus |

| Peripheral interface | RS232,USB |

| Correction method | Linear or nonlinear calibration, custom calibration curve |

| Rated power | 2000W |

| Dimensions (L×W×H) | 735mm×560mm×560mm |

| Net weight | 80kg |

| Power supply | 220V AC ±10% 50Hz |

| Temperature | 5℃~30℃ |

| Humidity | ≤85% |

CONTACT NOW