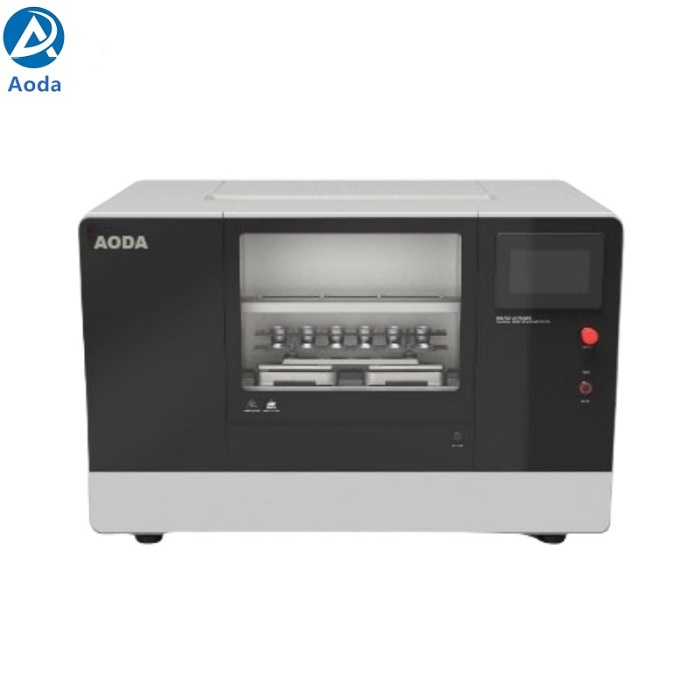

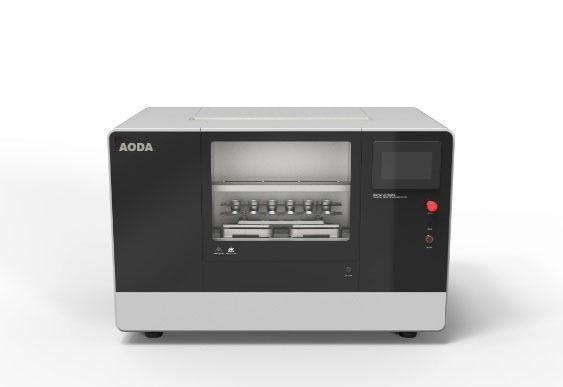

AFM3600 Fully automatic silicon carbon rod Fusion machine

Silicon carbon rod heating seriesMelting sampling equipmentA powerful assistant for high-precision XRF analysis...

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

AFM3600 Fully automatic silicon carbon rod Fusion machine

AFM3600 Full automatic Fusion machine is a silicon carbon rod heating furnace melting sample preparation equipment carefully developed by our company, mainly used for sample preparation of glass melting film method for XRF analysis.

Glass melting film method is an important method for preparing samples for XRF testing. It effectively reduces or even eliminates undesirable factors such as particle effect, matrix effect, mineral effect, etc. of samples, greatly improves the accuracy of XRF, and is widely used in steel, metallurgy, chemical industry, geology, cement and other industries.

AFM3600 Full automatic Fusion machine adopts carbon rod heating technology, with fast heating speed and uniform temperature field;

It is equipped with multiple high-precision thermocouple temperature sensors to monitor the temperature in the furnace in real time, and combined with PID temperature control technology to ensure the temperature accuracy and reproducibility during the melting process, which perfectly guarantees the quality of glass melting film;

It adopts intuitive full touch screen design, friendly human-machine interface and simple operation.

Adopting modern industrial design concepts, the high-temperature furnace and control unit are designed in an integrated structure, with a simple and beautiful appearance.

Using silicon carbon rod heating technology, the maximum temperature can reach 1400℃

Cold-to-cold operation mode, no heat radiation and scalding risk.

The lining of the high-temperature furnace is made of high-quality refractory materials to ensure the thermal stability and long life of the high-temperature furnace.

There is no ceramic rod above the melting crucible, which avoids the risk of pollutants falling during the melting process and achieves zero pollution in the melting process.

Automatically complete melting and casting: Users only need to complete the sample loading work, and they can start with one button: pre-oxidation-heating melting-vortex mixing-casting-cooling full process.

Platinum crucibles and molding molds are designed with heat-resistant ceramic protection frame devices (temperature resistance 1600℃) to extend their service life.

The built-in exhaust system can timely exhaust harmful gases generated during the melting process to ensure the health of the operator.

Multiple thermocouples are used to monitor the temperature in the high-temperature furnace in real time, and the temperature in the furnace is accurately controlled in combination with the PID temperature control program, ensuring the stability of the quality of the melt.

Six samples can be prepared at the same time, and the equipment is small in size and has a high overall cost-effectiveness.

AFM3600 Full automatic Silicon carbon rod heating Fusion Machine | |

Power | 8kW |

Heating method | Silicon carbon rod heating |

Temperature range | 1400℃ |

Temperature control accuracy | ±1℃ |

Crucible support material | Silicon nitride ceramic material, higher temperature resistance range |

Sample throughput | AFM3600 can prepare 6 samples at the same time |

Sample forming method | AFM3600 is automatic mold casting |

Control method | Operate the device through the touch screen |

Melting process | preheating → oxidation → melting (mixing) → mold casting → cooling molding |

Configurable parameters | Heating time, oxidation time, oxidation temperature, melting temperature, melting time, standing time, release agent addition time |

CONTACT NOW