Aoda ores and bulk materials Laboratory Jaw crushers

Laboratory jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials....

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Aoda ores and bulk materials grinding Laboratory Jaw crushers

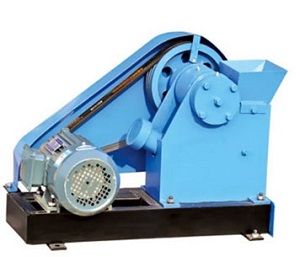

Laboratory jaw crushers are mainly used for medium-sized crushing of various ores and bulk materials. It can crush materials with compressive strength not more than 320Mpa. It is divided into coarse crushing and fine crushing.

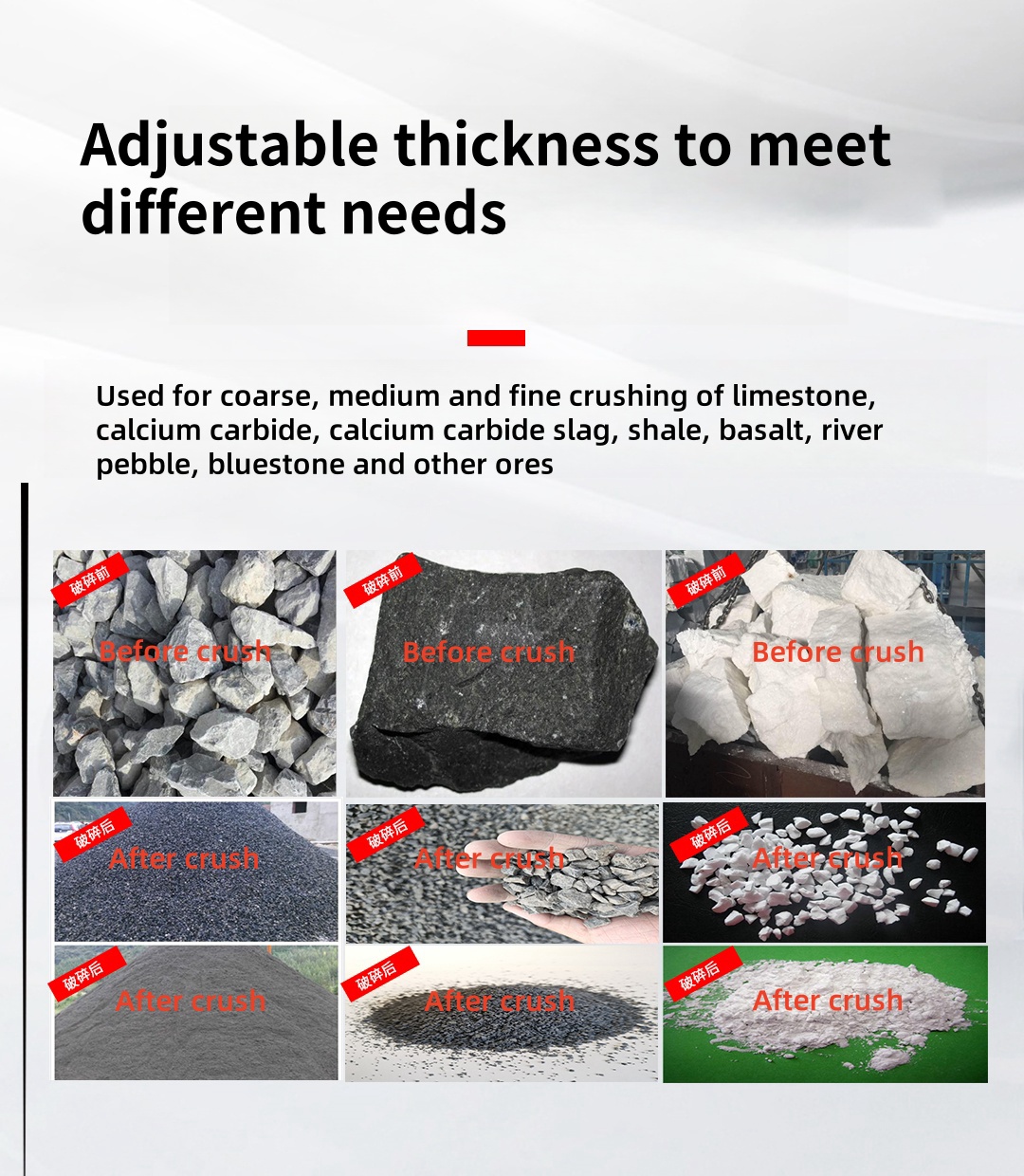

PE series jaw crusher has complete specifications, and its feed size is 125mm~1200mm. It is the primary crushing powder equipment. This equipment is mainly used for coarse, medium and fine crushing of various ores such as limestone, calcium carbide, calcium carbide slag, shale, basalt, river pebble, bluestone, etc. It has good effect in cement plants, sand and gravel plants, stone plants, thermal power plant desulfurization, calcium carbide plants, and is widely used in mining, metallurgy, chemical industry, building materials, water conservancy, transportation and other industries.

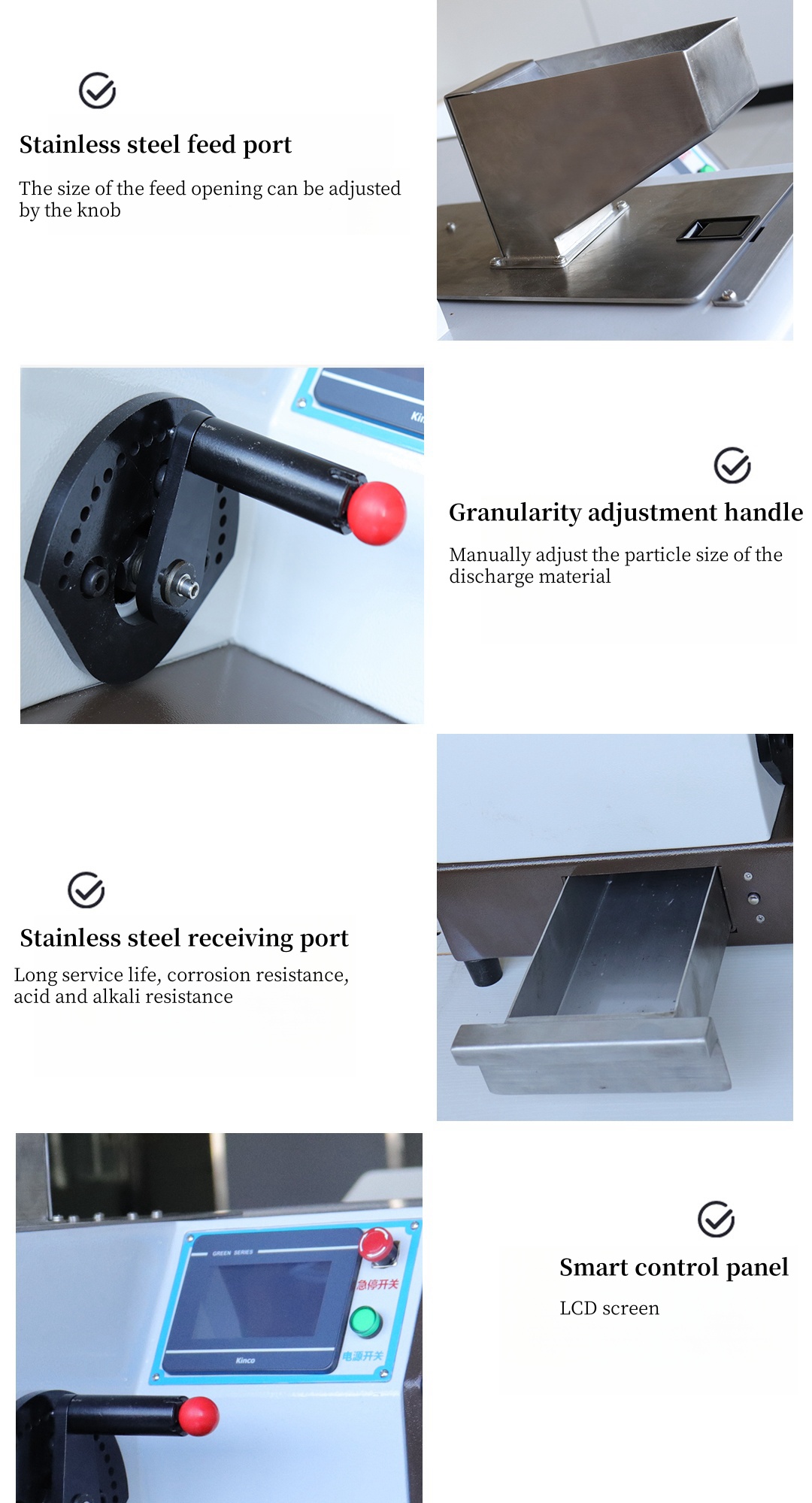

The main structure of the laboratory jaw crusher is composed of a frame, an eccentric shaft, a large pulley, a flywheel, a side guard plate, a toggle plate, a toggle plate back seat, a gap adjustment screw, a reset spring, a fixed jaw plate and a movable jaw plate, among which the toggle plate also serves as an insurance. The crushing method of this series of jaw crushers is a flexural extrusion type. The motor drives the belt and the pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate to approach the fixed jaw plate. At the same time, the material is squeezed, rubbed, and crushed. When the movable jaw moves downward, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the crushed material is discharged from the lower opening of the crushing chamber. As the motor rotates continuously, the movable jaw plate of the crusher performs periodic crushing and discharging, realizing mass production.

| Feeding sample size | <35mm |

| Output size | 0.01~8mm |

| Rotation speed of moving jaw | 560rpm |

| Rotation speed | 1400rpm |

| Motor power | 0.75KW |

| Power supply | AC220V50Hz |

| Weight | 115kg |

| Dimensions(L*W*H) | 73x51x57cm |

| Jaw crusher | Planetary ball mill | Roller ball mill |

|  |  |

CONTACT NOW