Aoda LGJ-10 Laboratory small scale Vacuum Freeze Dryer

Vacuum Freeze Dryer Comes with 4-6 layers of stainless steel trays. Suitable for the freeze-drying of bulk (liquid, paste, solid) conventional materials....

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Aoda LGJ-10 Laboratory small scale Vacuum Freeze Dryer

This series of freeze dryers are benchtop, basic models widely utilized in fields such as medicine, pharmaceuticals, biological research, chemistry, and food industries. Designed for laboratory use, they meet the requirements for most routine freeze-drying tasks. With their compact size and user-friendly features, these freeze dryers offer a cost-effective solution for preserving samples and products. They are essential tools for professionals seeking efficient and reliable freeze-drying capabilities.

It comes with 4-6 layers of stainless steel trays. Suitable for the freeze-drying of bulk (liquid, paste, solid) conventional materials.

LGJ-10 Vacuum Freeze dryer advantage

1. Integrated Design: Compact, leak-free, and user-friendly with no external flanges. Its small footprint makes it ideal for various laboratory settings. Our product is designed as a one-piece unit for easy operation without the need for intricate installation.

2. GLP-Compliant Materials: All materials in contact with the product are made from inert materials, fully complying with GLP requirements to ensure reliable and accurate experimental results.

3. Corrosion-Resistant Design: Both the cold trap and workbench are constructed from stainless steel, offering corrosion resistance and easy cleaning, thus extending equipment lifespan and reducing maintenance costs.

4. Safety-Ensured Valves: Our in-house designed and manufactured all-stainless-steel inflation (venting) valves guarantee safety, corrosion resistance, and eliminate the risk of leaks.

5. Pre-Freezing Function: With a generously sized cold trap opening and a sample pre-freezing feature, there's no need for an additional low-temperature freezer.

6. Gas Flow Control Technology: Utilizing specialized gas flow control technology ensures even ice capture in the cold trap, enhancing ice-capturing efficiency and ensuring successful experiments.

7. Efficient and Energy-Saving Compressor and Vacuum Pump: We use internationally renowned brand compressors and vacuum pumps, offering high efficiency, long service life, and low noise, ensuring equipment reliability.

8. Modular Control System: Featuring a next-generation modular controller and advanced control system, it maximizes process reliability and repeatability. The high-resolution 7-inch embedded LCD touchscreen provides ease of operation.

9. Intelligent Data Logging System: Real-time recording and display of cold trap temperature, sample temperature, and vacuum level curves. Data can be exported for browsing, printing, and various operations via a computer, enhancing data visualization management.

10. User-Friendly Interface: The human-machine interface displays real-time system status, supports flexible switching between Chinese and English, and allows for vacuum unit flexibility. The robust warning system includes alerts for high ambient temperatures, vacuum pump oil changes, instrument run time, sensor malfunctions, compressor and vacuum pump operation time, and more.

11. Comprehensive Protection Features: This includes compressor startup delay protection, compressor and vacuum pump short-circuit overload protection, ensuring both equipment and user safety.

12. Intelligent Electric Defrosting: Uses safe voltage, significantly improving defrosting efficiency while reducing maintenance costs.

LGJ-10 Vacuum Freeze dryer specification

LGJ-10S Standard | LGJ-10T Top-press | LGJ-10SM | LGJ-10TM | LGJ-10E | |

Freeze Drying Area | 0.12㎡ | 0.08㎡ | 0.12㎡ | 0.08㎡ | - |

Cold Trap Temperature | ≤-60℃, Optional ≤-80℃, ≤-110 (no-load) | ||||

Vacuum Level | <5Pa (no-load) | ||||

Water Capture Capacity | 3-4kg/24h | ||||

Material Tray | 200mm, 4 layers (Optional: 6 layers) | 180mm, 3 layers | 200mm, 4 layers (Optional: 6 layers) | 180mm, 3 layers | - |

Overall Power | 970w | ||||

Main Unit Weight | 41kg | ||||

Dimensions (mm) | 615×450×370 | 615×450×370 | 615×450×370 | 615×450×370 | 615x450x370 |

Loadable Materials | 1.2L/kg | 0.8L/kg | 1.2L/kg | 0.8L/kg | - |

Loadable Vials | Ф12mm:492 | Ф12mm:492 | - | ||

Ф16mm:279 | Ф16mm:279 | - | |||

Ф22mm:147 | Ф22mm:147 | - | |||

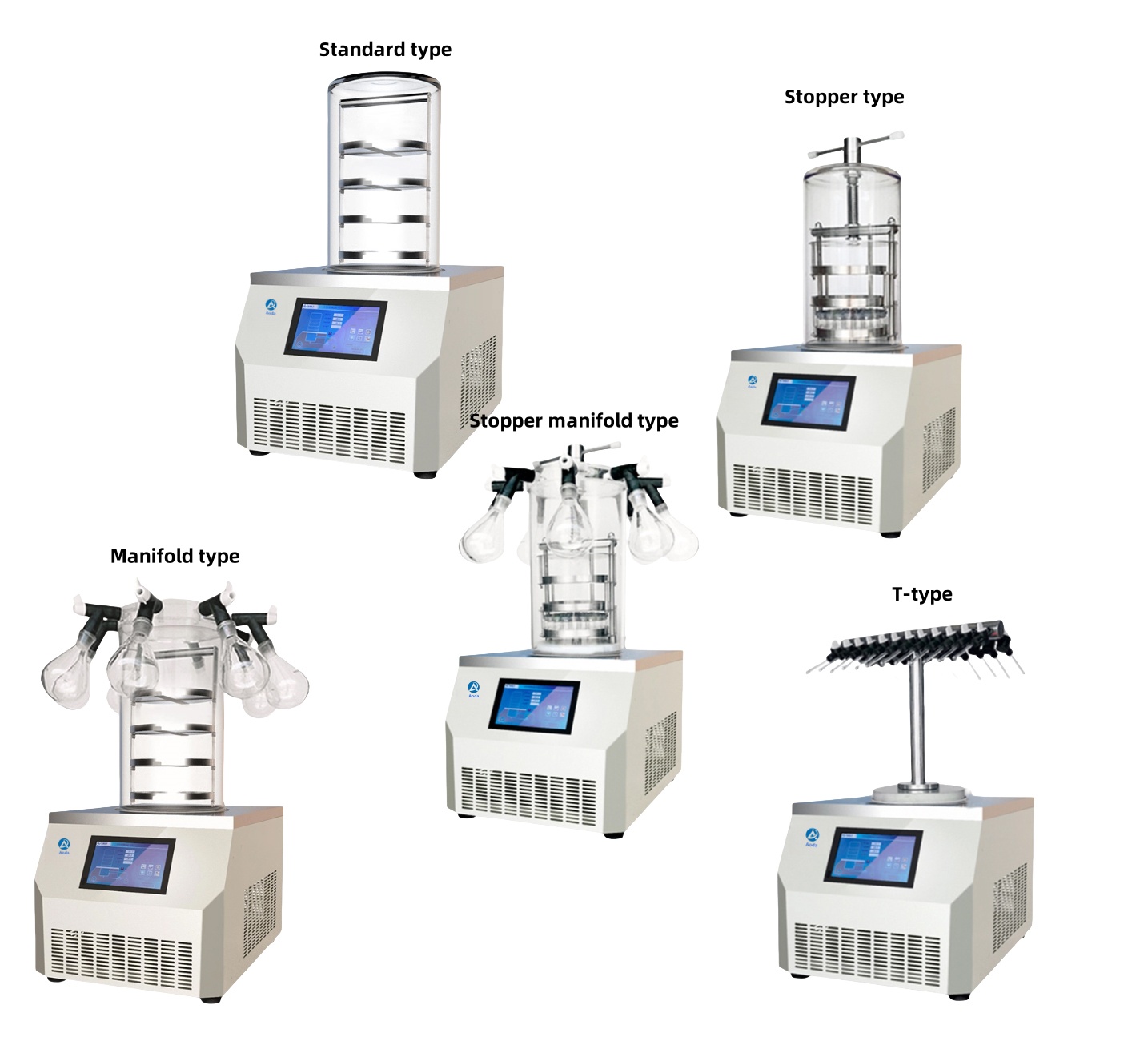

Standard Type: Comes with 4-6 layers of stainless steel trays. Suitable for the freeze-drying of bulk (liquid, paste, solid) conventional materials.

Stopper Type: Equipped with 3 layers of stainless steel trays with adjustable spacing. It is suitable not only for the freeze-drying of bulk (liquid, paste, solid) conventional materials but also for the drying of materials in vials. During freeze-drying preparation, materials can be divided into vials as needed, sealed with caps, and then subjected to freeze-drying. After drying, the pressure cover device can be used to move and seal the vials in a vacuum state, making them suitable for long-term storage.

Manifolds Type: Features 4-6 layers of stainless steel trays and an external hanging bottle attachment. Suitable for the freeze-drying of bulk (liquid, paste, solid) conventional materials and can also accommodate vials or wide-mouth bottles for drying. The external attachment is independent of the drying process and can be disassembled at any time. It can be used in conjunction with a concentrator to achieve both freeze-drying and concentration.

Stopper with Manifolds: Combines the features of the pressure cover type and the regular type with multiple manifolds.

T-Type (Ampoule Tube): Equipped with 24 ampoule tube interfaces. Suitable for freeze-drying ampoule tubes containing microorganisms such as bacteria and fungi for preservation.

CONTACT NOW