AODA Laboratory vacuum emulsification reactor

Laboratory vacuum emulsification reactor is used for dispersion, mixing, emulsification, homogenization, stirring and dissolving...

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

AODA Laboratory vacuum emulsification reactor

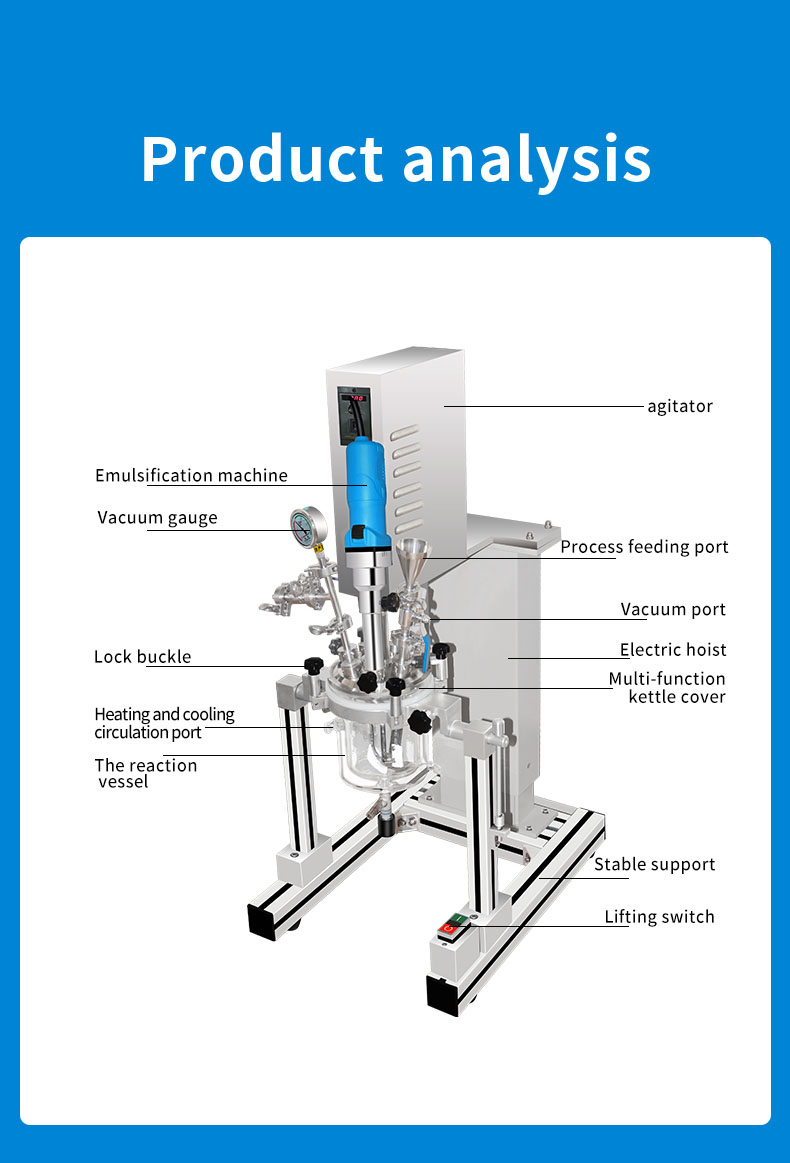

Laboratory vacuum emulsification reactor: realize the process of material dispersion, emulsification, homogenization and mixing under vacuum or pressure environment.

It can be equipped with a variety of high-viscosity stirrers, high-shear homogenizers, and reliable vacuum sealing systems and temperature control systems. Various sensing and detection systems can simulate industrial production in a laboratory environment.

At present, the laboratory processing capacity is: 1L, 2L and other series.

Laboratory vacuum emulsification reactor is used for dispersion, mixing, emulsification, homogenization, stirring and dissolving in the laboratory. The whole reaction process of stirring, homogenizing, emulsifying, dispersing, mixing, etc. of the material can be observed through a glass kettle under vacuum or pressure conditions, and it can also be homogeneously emulsified and dispersed by stainless steel pressure and high temperature.

● Production of cheeses, lotions, lotions and preparations of fats in the pharmaceutical and cosmetic industries;

● Mix solids such as calcium carbonate, talc, titanium oxide, etc. with the emulsion;

● High shear dispersion emulsification or polymer polymerization reaction stirring in lithium battery industry;

● Grinding and dispersing solids and fibers in liquids and polymers. Such as glue strong vacuum stirring;

● It can measure the temperature, pressure, viscosity, PH, etc. of materials at the same time. The material can also be heated or cooled.

Model | AHR-2L Laboratory vacuum emulsification reactor |

Item no | 1018002001 |

Power Supply | 220V 50/60HZ |

Max mixing capacity(ml) | 500-2000 |

Max emulsification(ml) | 1000-2000 |

Working Temperature(℃) | 170 |

Reach vacuum | -0.097---0.02mpa |

Viscosity | 100000mpas |

Mixing Speed Range | 0-230rpm |

Propeller | Anchor type ribbon scraping wall stirring slurry |

Scraper Material | Silicone Rubber |

Homogenizer motor power | 1050W |

Homogenizer speed | 7500-30000rpm |

Working head | 25DG |

Reactor lid opening | Homogenizer port + hopper port + temperature measuring port + vacuum port + 3 spare ports |

Lifting bracket distance | 350mm |

Sample touch material | SS316L、borosilicate glass、FKM10 |

Outer diameter of vacuum port | 10mm |

Outer diameter of inlet and outlet of glass kettle jacket | 12mm |

Allowable ambient temperature(℃) | 5-40 |

Allowable ambient Humidity(%) | 80 |

Exterior Dimension(mm) | 400*390*780 |

Standard weight(kg) | 38 |

CONTACT NOW