Aoda 2L~100L Low temperature grinding laboratory ball mill

Low temperature planetary ball mill is mainly used in material grinding process which requires strict temperature control....

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Aoda 2L~100L Low temperature grinding laboratory ball mill

Low temperature planetary ball mill is a combination of planetary ball mill and refrigeration device. Most materials will heat up during high-speed grinding due to friction or exothermic reaction, which may change the physical and chemical properties of the materials and produce negative grinding effects. Low temperature planetary ball mill is mainly used in material grinding processes that require strict temperature control.

Application

Low-temperature planetary ball mills are widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, environmental protection and other departments. They are suitable for the production of electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, lithium manganese oxide, catalysts, phosphors, long afterglow luminescent powder, rare earth polishing powder, electronic glass powder, fuel cells, zinc oxide varistors, piezoelectric ceramics, nanomaterials, disc ceramic capacitors, MLCC, thermistors (PTC, NTC), ZnO varistors, dielectric ceramics, alumina ceramics, zirconia ceramics, phosphors, zinc oxide powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite and other products.

Feature

Low temperature planetary ball mill is a combination of planetary ball mill and air cooling device. The air cooling device uses the principle of air conditioning compression refrigeration. The cold air circulation quickly takes away the heat generated by grinding. According to the difference in ambient temperature, the ball milling space temperature can be controlled at 5-15℃. It is mainly used for ultra-fine grinding of materials under low temperature process. The air cooling device has a simple structure, convenient operation, easy maintenance and low energy consumption.

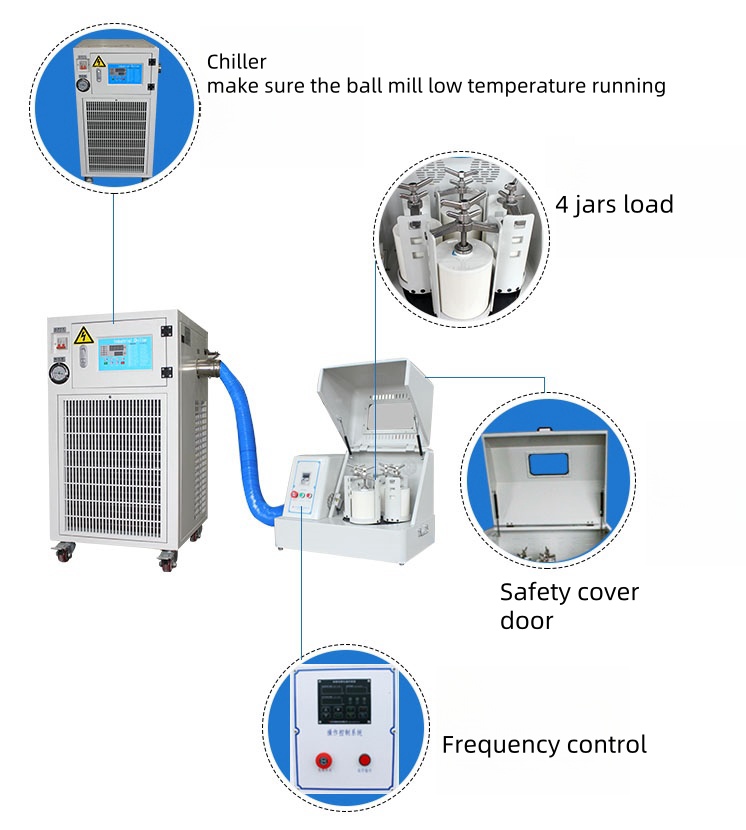

Constructure

Technical parameters of Planetary ball mill

Model | XQM-2L | XQM-4L | XQM-8L | XQM-10 | XQM-12L | XQM-20L | XQM-40L | XQM-60L | XQM-100L |

Capacity(L) | 2 | 4 | 8 | 10 | 12 | 20 | 40 | 60 | 100 |

Drive mode | Gear drive | ||||||||

Operate mode | 2 or 4 mill jar work together | ||||||||

Max loading capacity | 2/3 of mill jar volume | ||||||||

Voltage | AC220V50Hz | 380V50Hz | |||||||

Revolution Speed | 35-335 | 35-290 | 35-215 | 20-195 | 27-174 | 27-160 | |||

Rotation Speed | 70-670 | 70-580 | 50-430 | 40-390 | 40-260 | 40-240 | |||

Total Timing | 1-9999 | ||||||||

Alternating Run Time of Forward & Reversal Rotation(min) | 1-999 | ||||||||

Power(KW) | 0.75 | 1.5 | 4 | 5.5 | 7.5 | 11 | |||

Jars volume | 50-500ml | 250-1000ml | 1-2L | 1-2.5L | 1-3L | 2-5L | 5-10L | 10-15L | 20-25L |

Sample | Soil≤10mm;Others ≤10mm3mm | ||||||||

Noise(db) | 60 | 65 | 68 | ||||||

Speed adjustment | Frequency control | ||||||||

N/W(kg) | 93 | 150 | 330 | 468 | 900 | 1250 | |||

Dimension(cm) | 75*47*56 | 90*60*64 | 120*75*90 | 140*85*116 | 160*99*125 | 175*114*133 | |||

If choose machine volume bigger than 20L,We suggest user choose the lifter to work together. Like below

Product images

Optional mill pots and balls for Planetary ball mill

We provide all kinds of mill pots and balls in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

CONTACT NOW